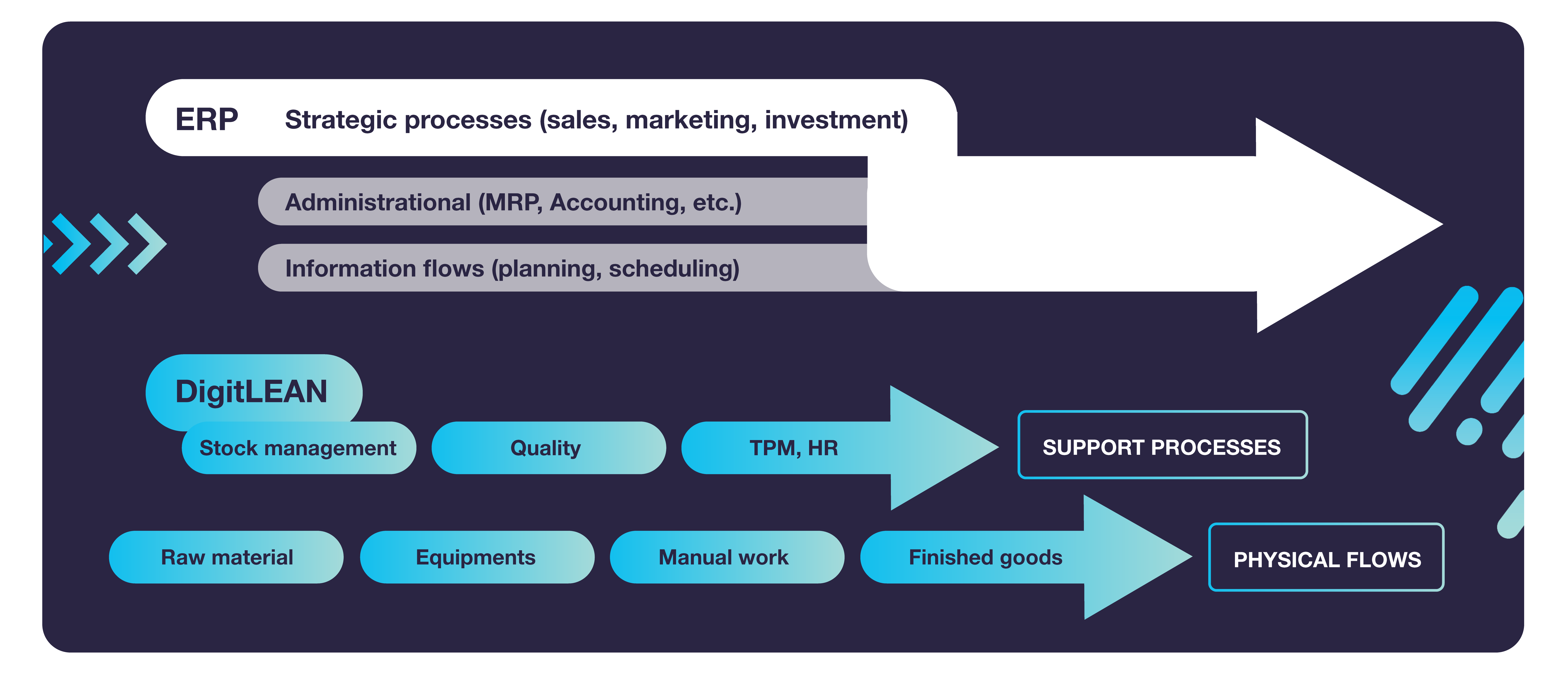

Decades of experience gained in the introduction of traditional LEAN and the enhancement of operational efficiency combined with data collection and evaluation solutions ensured by the available modern technology enable LEAN to exploit its real potential.

With our Digital LEAN™ approach we aim to transform management systems into a truly living and efficient structure by powering them with the modern toolkit of Industry 4.0.

Our solution has been inspired concept like LEAN philosophy, continuous improvement and the learning organization. Digital LEAN™ is a unique combination of the modern 21st century digital technology and internet communication of production equipment as well as the Archamonde’s 25-year experience in LEAN implementation.

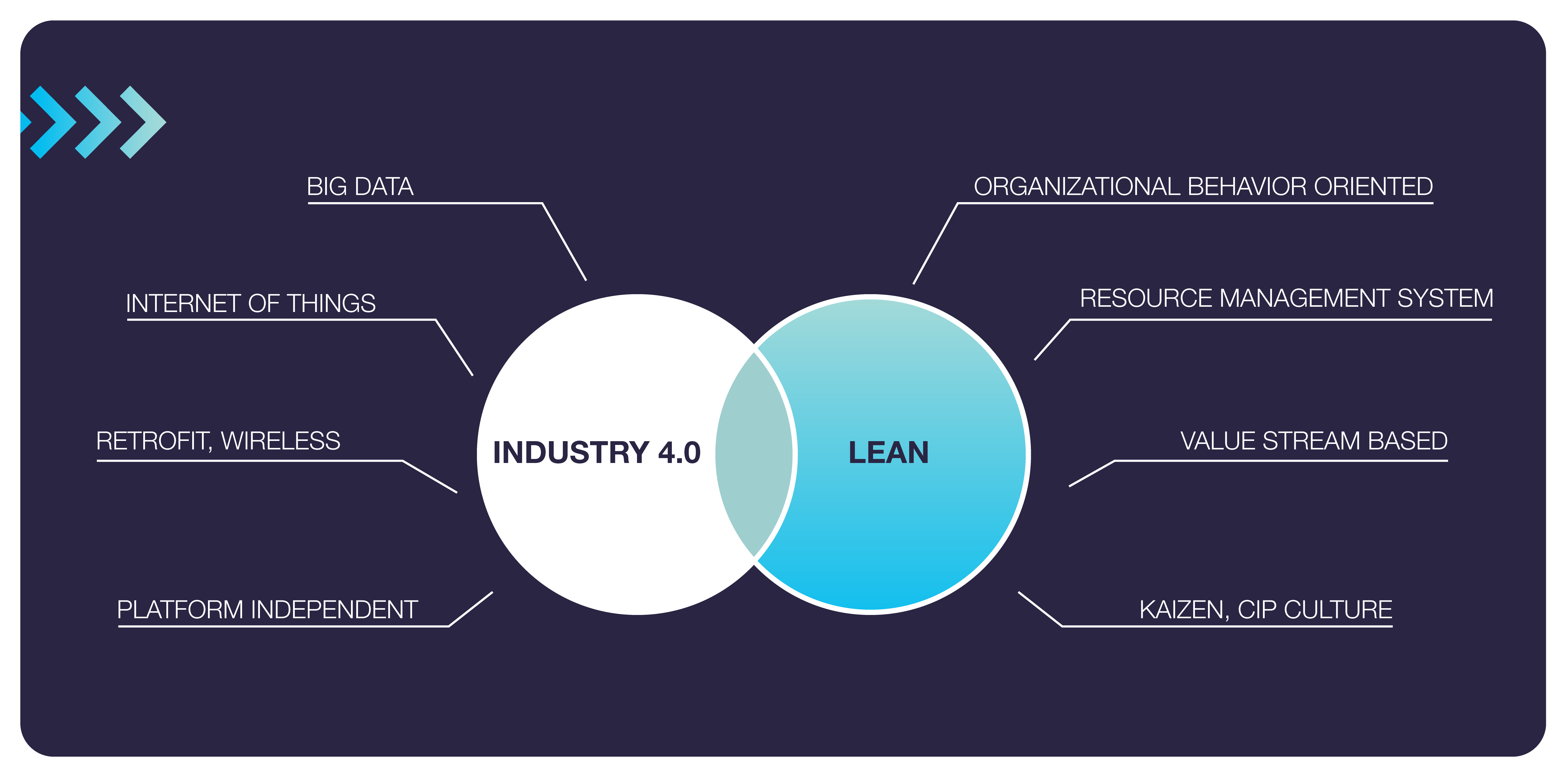

Our solution means the realization of Industry 4.0. The system we offer is based on LEAN complemented by a Digital LEAN Assistant system.

The basis of the approach of Digital LEAN ™ is to transform management systems by means of IT tools into real-life systems that have permanent interaction with the operating person. We believe that the value of a system is defined by the extent of how much the operating people understand and use them.

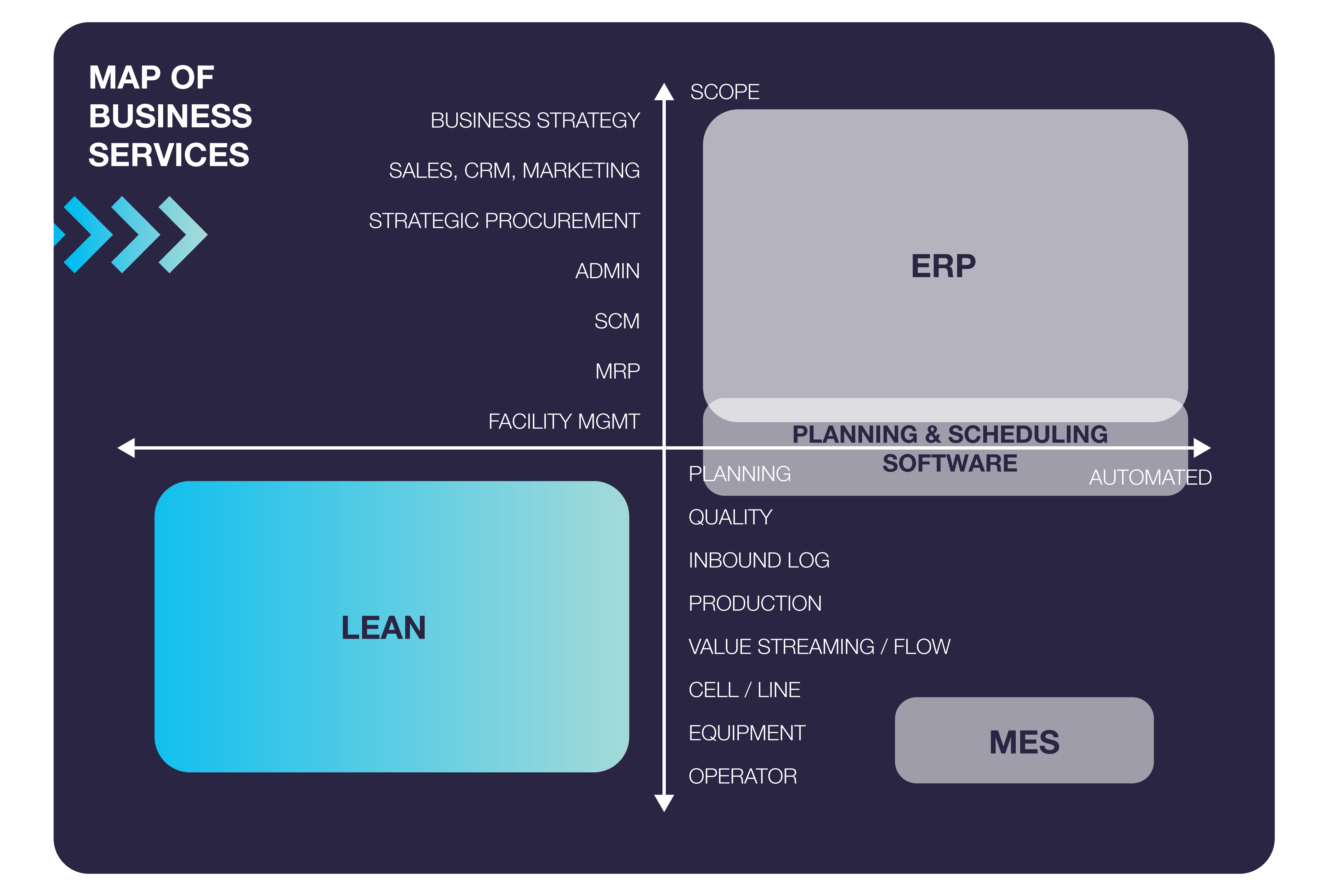

POSITIONING

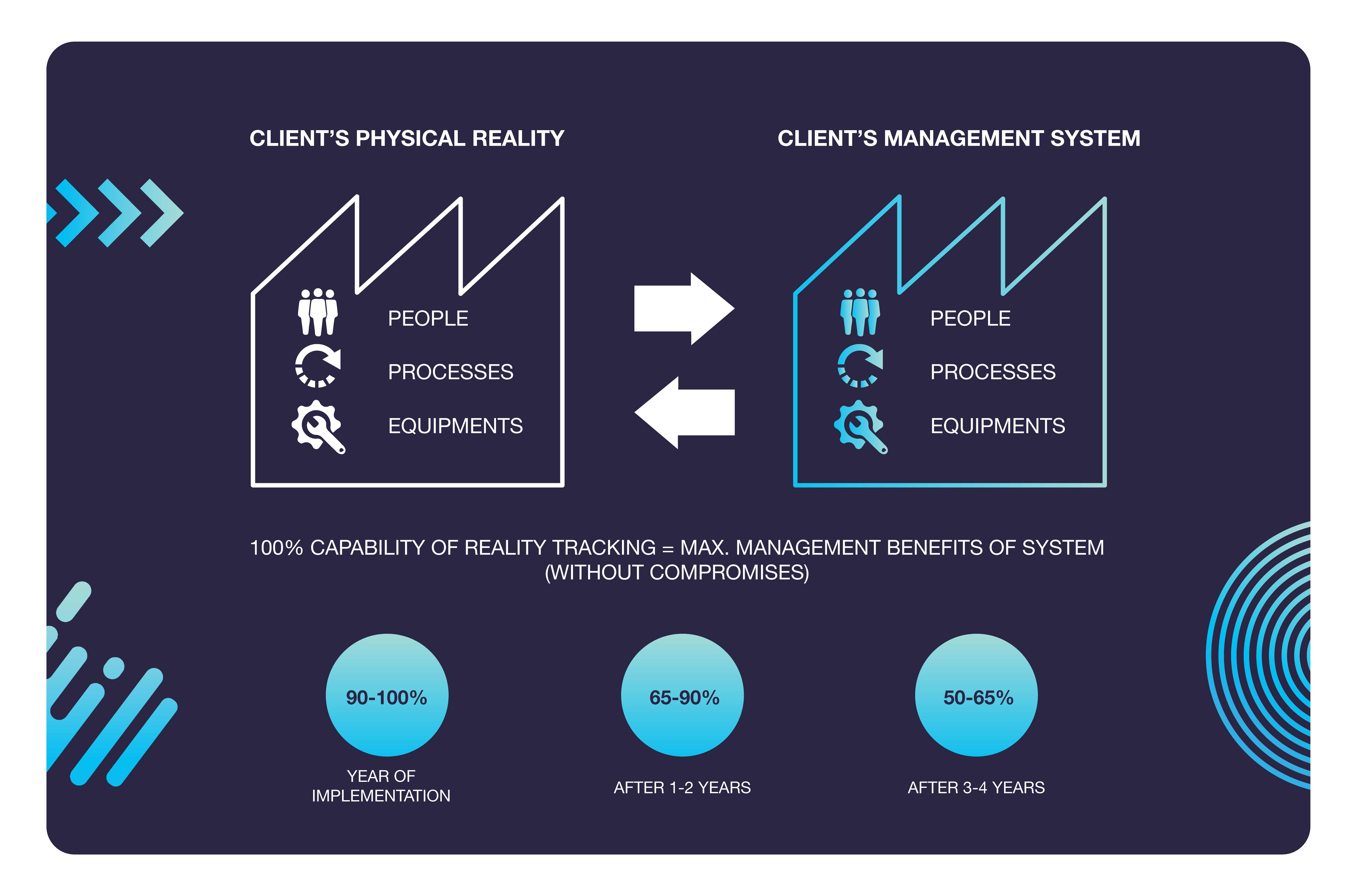

Digital LEAN™ is a complex business management innovation as by reaching the limits of the traditional management concepts we realized that only those solutions have justification in modern business that can fully create the customer's reality. The trend of Industry 4.0 and IoT (Internet of Things) makes it possible, as they have now made those technologies available that enables a high degree of customization by the 100% replication of the customer's business processes, and besides it is suitable for digital monitoring of those devices that represent the generation preceding the information age.

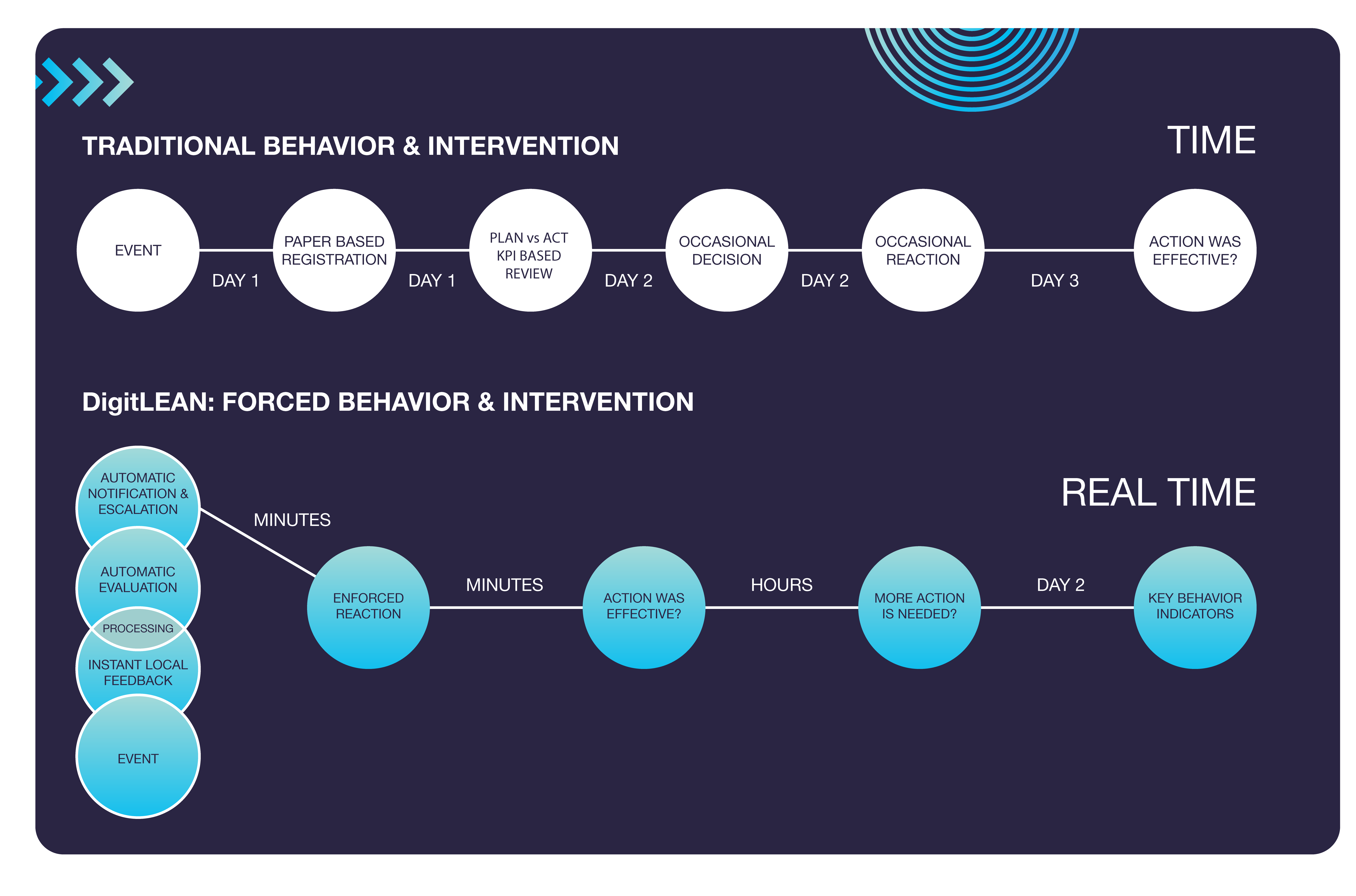

Many organizations have faced unsuccessful introduction of LEAN. Our digital solution allows the focus of practical efforts to shift from the inaccurate and overdue data production to measurable interventions based on real data.

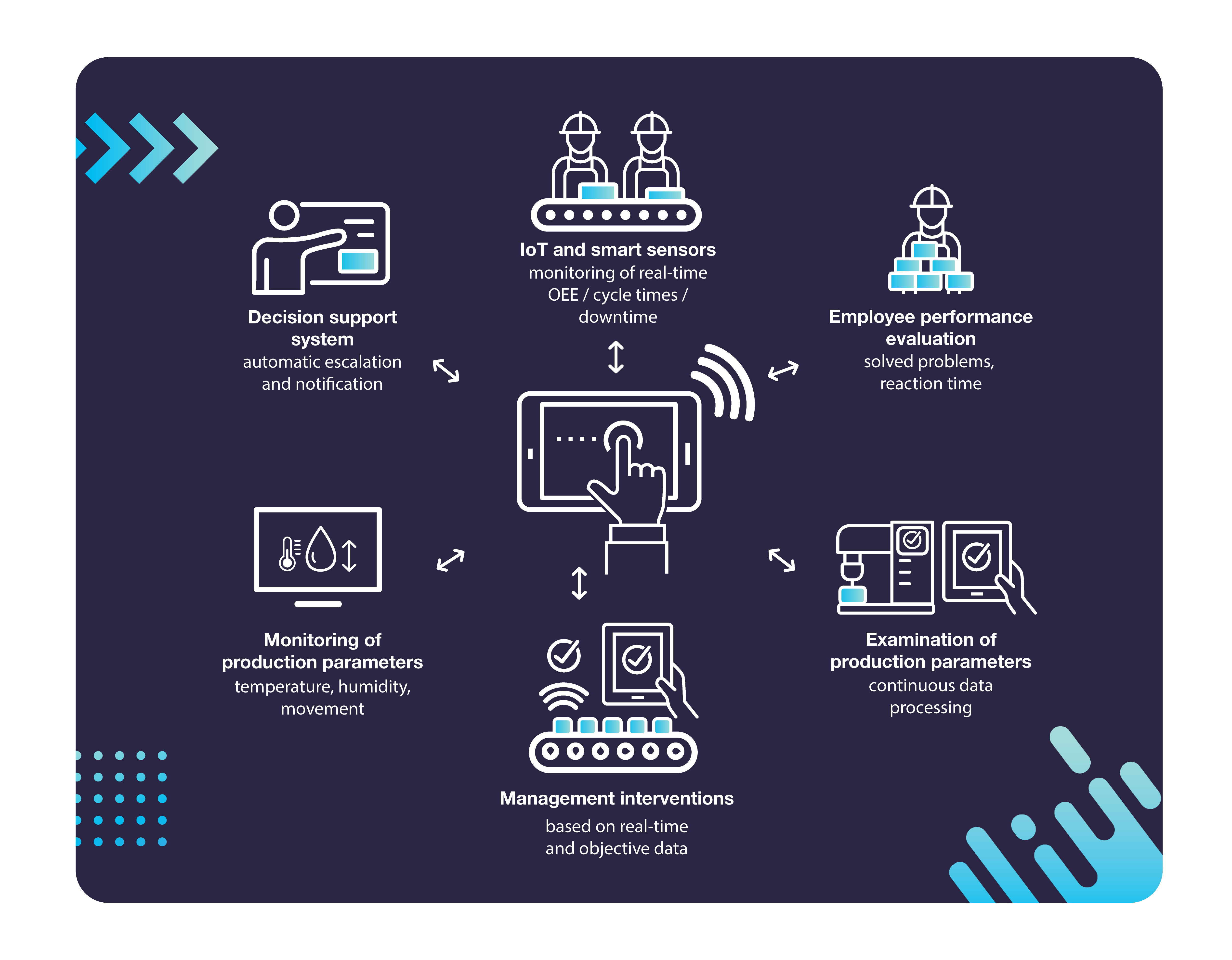

Elean, your Digital Lean Assistant, is constantly at service of your LEAN system. It collects, transfers and organizes the necessary data and notifies participants involved in the solution in an intelligent way.

BENEFITS

REAL-TIME PERFORMANCE MANAGEMENT

BEHAVIORAL ASSESSMENT

By linking real-time performance measurement and behavior traceability, the accountability of the members of the organization and the transparency of their activities increases, and thus a change in management behavior can be achieved. As a result of the speeding up of processes expectations related to the production of information have significantly increased, real-time response has become a key condition for competitiveness. In addition to real-time problem recognition, Digital LEAN™ also measures the effectiveness of management interventions through an automated notification and intervention system.

RESULT GUARANTEE

We can guarantee that the digital system usage based on our guidance results in a higher level of efficiency. This guarantee is the result of the difference between the best demonstrated performance and the level of efficiency achieved by the company.

ELEAN, YOUR DIGITAL LEAN ASSISTANT

ELEAN is a customizable, platform independent system for data collection and assessment that supports real-time and efficient management of LEAN controlling production processes. By using online reporting system, it speeds up the decision-making by the management which leads to a faster and more valid intervention. ELEAN is a constant voice to call for higher performance.

FEATURES

Digital LEAN is a real-time management system developed for dealing with real manufacturing problems. In terms of its functions, it exceeds traditional LEAN systems by using digital technology.

LEAN because it is behaviour, customer and result oriented. The wide range of digital devices is only effective if it is able to facilitate human work. The aim of Elean Digital Assistant is to facilitate cooperation.

Measuring production loss is essential for effective operation. Elean, your Assistant is able to digitalize data collection. Unlike papers it represents reality.

A typical production environment consists of devices and equipment of different types and ages combined with semi-automatic and manual operations. The independent and retrofit solutions of Digital LEAN™ platform offer the only way to bring these to a unified platform.

The usefulness of the system is rooted in the most accurate virtualization of the customer's unique reality and system. The more the compromise the less the efficiency of the system. Digital LEAN does not make compromises; it always aims to represent objective reality.

Your collected data is always secure and accessible anywhere from any device. Thanks to 'Digital LEAN Cloud Analytics' you can learn about the real performance of your organization (real-time data on efficiency, Andon, telemetry, management behavior indicators).

Detecting the difference is only step zero in problem solving. Digital LEAN measures losses in real time and escalates them to the responsible person in a predetermined way. By measuring the time elapsed between the notification and the intervention it is able to measure management behavior.